Okay, I know this to has been done to death but thought I would just give another one to demonstrate how easy this kit is to install to compliment all of the other similar threads out there.

Here is how the Transgo Jr. SK comes packaged.

![Image]()

Drain the transmission fluid. Before dropping the transmission pan get a large drip pan, large cookee sheet or a actual transmission drain pan like shown here. The point is to have something larger than the transmission pan itself. Once the pan is removed trans. fluid will rain down until the process is completed and the pan reinstalled.

![Image]()

Pull the internal filter down out of its bore. This may require some slight twisting and walking it out of the bore/seal.

![Image]()

This is what you should be looking up at.

![Image]()

While the internals are dripping off I took a few minutes to clean the pan. You can see there is minimal sludge in the pan which is perfectly normal. Actually a little more than this is actually normal, my transmission only has 80k miles on it and this is the second time I have serviced it in the 5 years and 25k miles that I have owned it.

![Image]()

You will get a little more sludge off of the magnet but not much. What you don't want to see is metal peices. That would be bad.

![Image]()

The pan gaskets are reusable to a point. This is only the pans first time off so I chose to clean it up and reuse it. The filter kits run about $53.00 for the filter and gasket vs. only about $33.00 for just the filter. I chose to just purchase a replacement filter.

![Image]()

Now back under the truck. Disconnect all of the wiring from the solenoids and the PSM. Be very careful with the locking tabs on these connectors as they tend to get brittle over time and throughout many heat cycles. There are two small wire retainers that need to be temporarily removed to move the wiring harness out of the way. Remove these two wire clips, move the wiring harness and reinstall the two wire clips. These hold solenoids into the valve body and you could drop and lose or damage them if they fall out.

![Image]()

![Image]()

Reinstall them once the wiring harness has been removed.

![Image]()

Carefully move the wiring harness out of the way. Be careful to not use force and merely use something to hold it back out of the way. I use a bungee cord to loosely hold it against the exhaust pipe without pulling or tugging on the wires themselves.

![Image]()

Personally I don't like to have a trail of oil across my shop floor so rather than remove the valve body and hurry across to the bench I have a large pan ready to set the valve body into it. This way I can carry it to the bench and use the same drip pan to perform my work on the valve body and prepare it for reinstallation.

![Image]()

I prefer to break all of the bolts loose on the valve body while it is still held firmly in the transmission. This is much easier than just removing the ones holding the valve body to the transmission case and then chasing the valve body around the bench while trying to remove the remainder that hold the two halves of the valve body together. Once all of the bolts are broken loose I remove only the bolts that hold the valve body assembly to the transmission so it doesn't fall apart before I am ready for it to.

I leave this bolt until last and remove it when I have ahold of the valve body.

![Image]()

There is a small pin right here on the shift comb where it attached to the manual shift valve. Be careful to not damage or loose this small pin. Once the last bolt is removed from the valve body, wiggle or walk the valve body off of the dowel pins and turn to disengage this pin from the shift linkage/comb.

![Image]()

Better view of the pin in previous picture.

![Image]()

To be continued in the next post.

Mike.

Here is how the Transgo Jr. SK comes packaged.

Drain the transmission fluid. Before dropping the transmission pan get a large drip pan, large cookee sheet or a actual transmission drain pan like shown here. The point is to have something larger than the transmission pan itself. Once the pan is removed trans. fluid will rain down until the process is completed and the pan reinstalled.

Pull the internal filter down out of its bore. This may require some slight twisting and walking it out of the bore/seal.

This is what you should be looking up at.

While the internals are dripping off I took a few minutes to clean the pan. You can see there is minimal sludge in the pan which is perfectly normal. Actually a little more than this is actually normal, my transmission only has 80k miles on it and this is the second time I have serviced it in the 5 years and 25k miles that I have owned it.

You will get a little more sludge off of the magnet but not much. What you don't want to see is metal peices. That would be bad.

The pan gaskets are reusable to a point. This is only the pans first time off so I chose to clean it up and reuse it. The filter kits run about $53.00 for the filter and gasket vs. only about $33.00 for just the filter. I chose to just purchase a replacement filter.

Now back under the truck. Disconnect all of the wiring from the solenoids and the PSM. Be very careful with the locking tabs on these connectors as they tend to get brittle over time and throughout many heat cycles. There are two small wire retainers that need to be temporarily removed to move the wiring harness out of the way. Remove these two wire clips, move the wiring harness and reinstall the two wire clips. These hold solenoids into the valve body and you could drop and lose or damage them if they fall out.

Reinstall them once the wiring harness has been removed.

Carefully move the wiring harness out of the way. Be careful to not use force and merely use something to hold it back out of the way. I use a bungee cord to loosely hold it against the exhaust pipe without pulling or tugging on the wires themselves.

Personally I don't like to have a trail of oil across my shop floor so rather than remove the valve body and hurry across to the bench I have a large pan ready to set the valve body into it. This way I can carry it to the bench and use the same drip pan to perform my work on the valve body and prepare it for reinstallation.

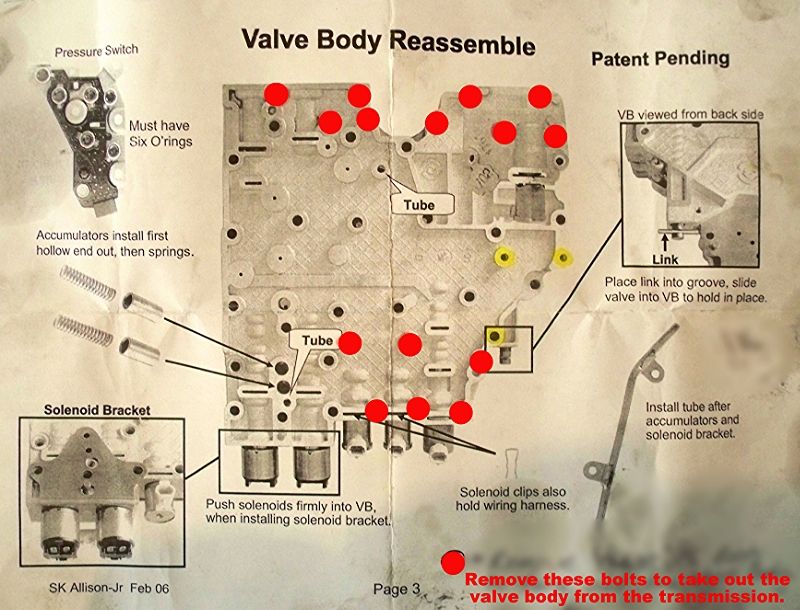

I prefer to break all of the bolts loose on the valve body while it is still held firmly in the transmission. This is much easier than just removing the ones holding the valve body to the transmission case and then chasing the valve body around the bench while trying to remove the remainder that hold the two halves of the valve body together. Once all of the bolts are broken loose I remove only the bolts that hold the valve body assembly to the transmission so it doesn't fall apart before I am ready for it to.

I leave this bolt until last and remove it when I have ahold of the valve body.

There is a small pin right here on the shift comb where it attached to the manual shift valve. Be careful to not damage or loose this small pin. Once the last bolt is removed from the valve body, wiggle or walk the valve body off of the dowel pins and turn to disengage this pin from the shift linkage/comb.

Better view of the pin in previous picture.

To be continued in the next post.

Mike.